Drehen Equipments & Solutions is a reliable Air Classifying Mill Manufacturers, Suppliers, Exporters, and Dealers in UAE. As an outfit devoted to innovation and quality, we supply sophisticated air classing millers to the engineer to address the precise requirements of the fine particle size and the classification dealing with the classification.

Being a prominent Air Classifier Mill Manufacturer, we serve a wide range of regions with high-demonstration solutions for manufacturing, supply, exports and needs. Our technical expertise and customer-oriented solutions make us a partner of choice for companies in the need of reliable milling solutions.

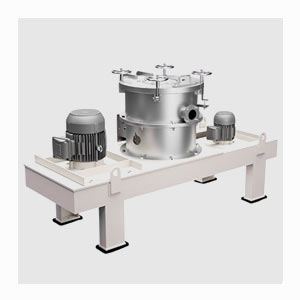

An Air Classifying Mill is a high-tech machine that combines grinding and air classification into one compact, efficient process. The mill works by conveying material through a grinding chamber, where high-speed rotors break down particle size by impact. Meanwhile there is an internal air particle separator which segregates the particles size wise which allows the finer particles to be removed and the larger or coarser particles to be recalculated back into the mill to continue the grinding. A consistent particle size is assured in the closed-circuit process that makes miller favorable where high precision is required such as chemicals, pharmaceuticals and even food processing. One special consideration to be given to the Air Classifying Mill employed to make the grinding of the heat-sensitive and the abrasive materials effectively.

Explore the various types offered by our leading Air Classifying Mill Manufacturers in UAE, designed for precise particle size control across diverse industries.

| Parameter | Specification |

|---|---|

| Material | Mild Steel, 10 ACM Liner |

| Capacity | 500 kg/h to 10 TPH |

| Motor Power | 5 kW to 100 kW |

| Rotor Speed | 2000 - 6000 RPM |

| Air Flow Rate | 1000 - 10000 m³/h |

| Grinding Fineness | 10 - 150 microns |

| Material of Construction | Mild Steel, SS 304, SS 316 |

| Automation | Semi-automatic to fully automatic |

| Control System | PLC-based with HMI touch screen |

| Safety Features | Overload protection, emergency stop |

Our Air Classifying Mill Suppliers in UAE offer advanced features like precise particle control, energy efficiency, and durable design:

| Feature | Description |

|---|---|

| High-Speed Rotors | Allow easy and effective reduction in the size of the particles so as to achieve homogeneous results. |

| Integrated Air Classifier | Offers precise proportion distribution of particle sizes to manufacture equal powder. |

| Energy-Efficient Motors | Reduce operation costs by using energies effectively. |

| Automated Controls | PLC-based system that allows convenient operation and operation monitoring via HMI. |

| Durable Construction | Constructed of SS 304 /316 to avoid wear and tear and corrosion. |

| Low Maintenance Design | The cleaning and maintenance are easy with quick access doors and easy removal parts. |

| Versatility | Works with heat-sensitive, abrasive, and tacky materials with zero inconveniences. |

| Compact Footprint | Design is space conserving, which allows the structure to fit facilities of different sizes and maximized workspace. |

As an Air Classifying Mill Exporters in UAE, we cater to a wide range of industries, given below;

The Drehen Equipments & Solutions as a reliable Air Classifying Mill Manufacturers, Suppliers, Exporters, and Dealers in UAE Experience in Classification and size reduction of particles. Our stress is on quality thorough testing, tailor made solutions to address different industry needs and after sales service of our products. We offer value-oriented services that are as per the global standards through our cost-effective prices and focus on performance, reliability, and customer satisfaction. Get a call back today on a personalized quote and see how we can help streamline your powder processing needs.

It is a kind of mill where the process of grinding and sizing are combined producing fine uniform powders. It has wide applications in the pharmaceutical industry, food processing and chemicals industries.

In this approach, the air stream is utilized in sorting the particles according to the size and density of the particle to enable the overall product particle distribution to be controlled perfectly.

It is equipment that is used in tandem with a ball mill so as to segregate fine particles in the grinding process thus overall increases efficiency and guarantees products of better quality.