Vortex Coolers - Innovative, Reliable, and Efficient Cooling Solutions- How it works

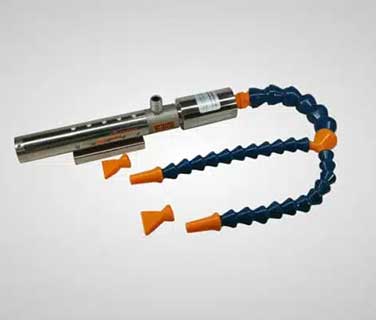

Vortex coolers—also known as vortex tubes or cold air guns—are advanced, maintenance-free cooling devices that operate without any moving parts, chemicals, or refrigerants. Instead, they utilize a fundamental physical principle known as the vortex effect to deliver effective and efficient cooling.

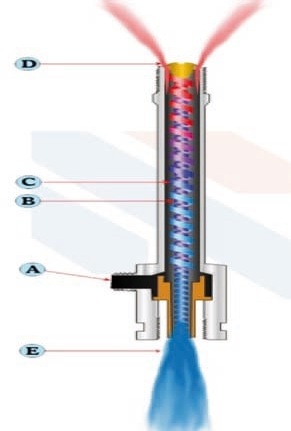

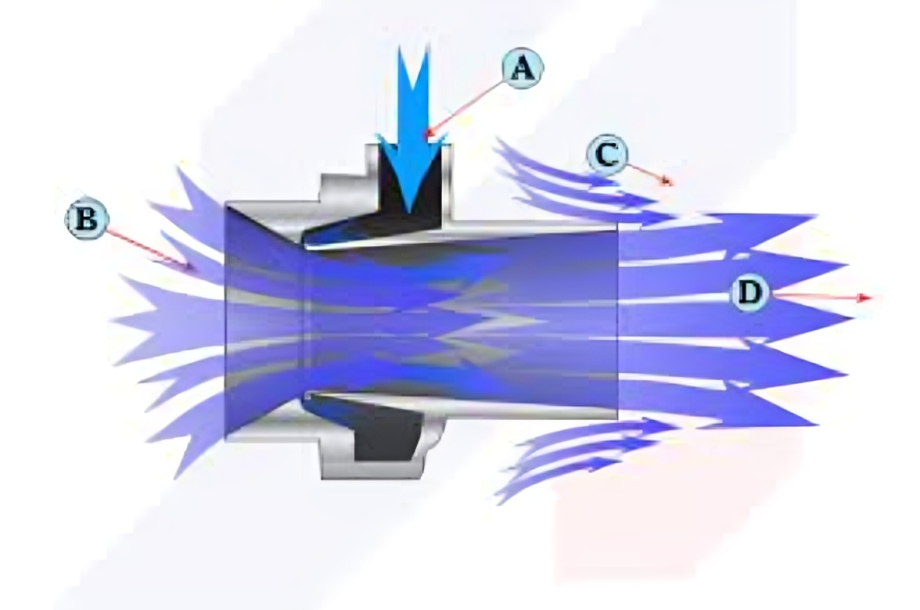

The vortex effect, also referred to as the Ranque-Hilsch effect, occurs when compressed air is injected into a specially designed cylindrical tube, creating a high-speed, spinning vortex. As the air spirals through the tube, it separates into two distinct air streams: one hot and one cold. This separation results from a rapid pressure drop within the vortex, which causes part of the air to cool dramatically—often to temperatures as low as -40°C or even lower, depending on the design and operating parameters of the cooler.

The cold air exits through the cold air outlet, providing an ideal solution for localized cooling in a variety of applications, including machinery, electronics, and industrial processes. Meanwhile, the hot air exits through a separate outlet and can be vented, redirected, or repurposed for tasks such as drying or warming.

Vortex coolers are a practical choice for environments requiring robust and maintenance-free spot cooling, particularly in areas where traditional refrigeration is impractical or undesirable.

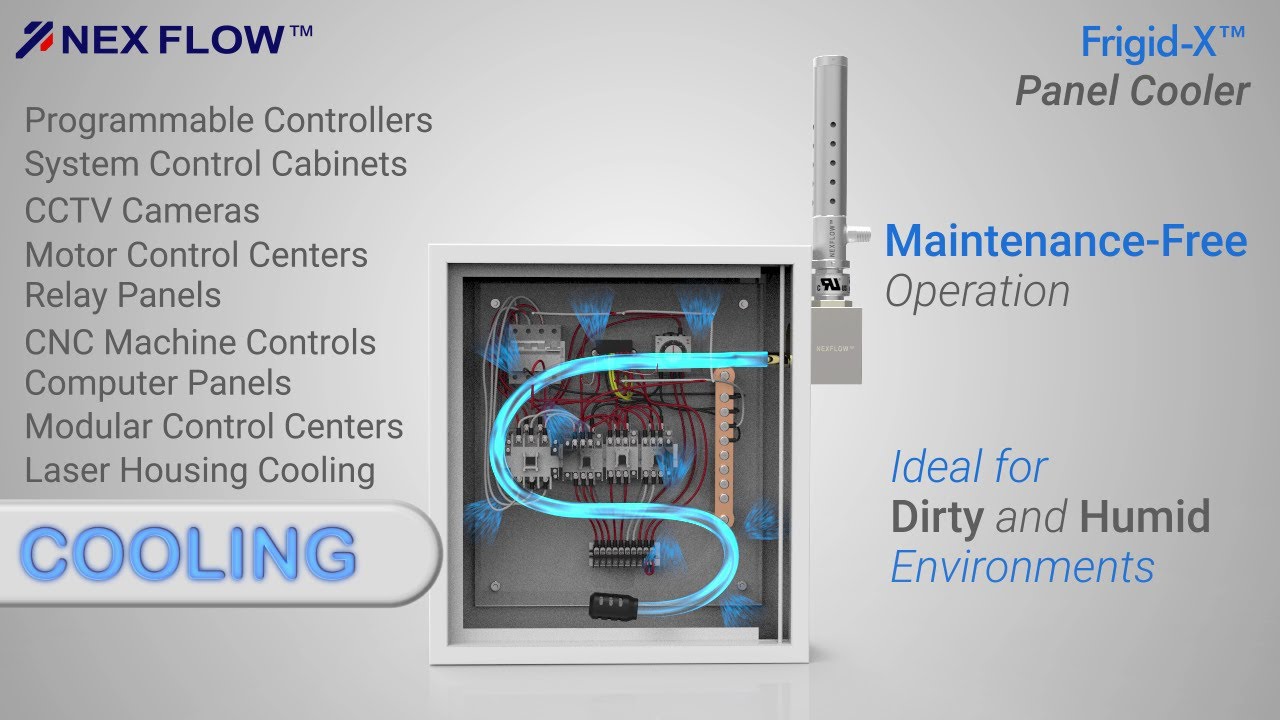

COOLING :

- Programmable Controllers

- System Control Cabinets

- CCTV Cameras

- Motor Control Centers

- Relay Panels

- CNC Machine Controls

- Computer Panels

- Modular Control Centers

- Laser Housing Cooling