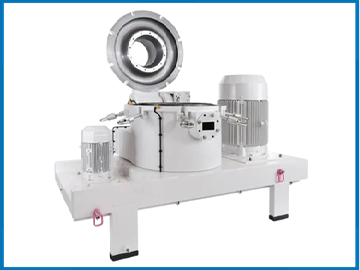

APF Standard

Up to 55% less differential pressure

Significantly reduced energy costs

New high density deep bed pleated filter medium

250% larger filtration surface compared to a conventional pleated element

Approx. 25% greater filtration surface compared to a conventional pleated element

Reduced flow velocity within the filtration medium makes APF series the market leader in efficiency and lowest pressure drop.