Drehen Equipments & Solutions is a reliable leader among Crusher Machine Manufacturers, Suppliers, Exporters, and Dealers in India, offering material size reduction products that are world-leading and proven. The mining, construction and recycling companies are the best suitable with our high performance machines. They are long lasting and reliable and give the highest productivity in heavy duty applications.

We also differentiate as trustworthy Crusher Machine Plant, providing Automatic Stone Crusher Machines with the lowest price in India. Our crushers are built for seamless integration and durable performance. With the backing of expert support, we offer tailor-made solutions to suit your production requirements.

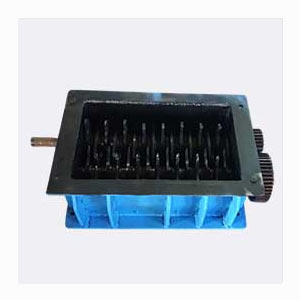

A Crusher Machine is high-strength industrial equipment employed in crushing of large rocks, ores, and such other hard items into smaller manageable particles. It functions by mechanical forces like compression, impact, or shear. Crusher machines are used in the various industries including mining, construction, recycling, and quarrying, where material reduction in size is vital. There are compact versions also for small operations, providing efficiency as well as flexibility in confined work areas.

We are the best Crusher Machine Suppliers in India that offers various kinds of Stone Crushers to different industrial needs.

| Parameter | Specification |

|---|---|

| Capacity | 50-1000 TPH |

| Power | 50-500 kW |

| Max Feed Size | Up to 1000 mm |

| Output Size | 0-300 mm |

| Weight | 10-200 tons |

| Material of Construction | High-grade steel |

| Automation | Semi-automatic to fully automatic |

| Control System | PLC-based with touch screen interface |

Our India Crusher Machine Exporters offer high-performance, advanced crushers built for durability, efficiency, and reliable performance across various industries.

| Feature | Description |

|---|---|

| High Crushing Efficiency | Generates maximum output using minimum energy expenditure to perform economical operations. |

| Durable Construction | The steel used is top quality ensuring that it can endure extreme conditions and give durability. |

| Adjustable Settings | Adjustable settings mean that the output size can be configured to meet specific needs of applications. |

| Easy Maintenance | Facilitates easy access to components for uncomplicated maintenance and minimized downtime. |

| Energy Efficiency | Optimized motors save energy without sacrificing high performance. |

| Safety Features | Features overload protection and emergency stop for increased operator safety. |

| Versatility | Processes a broad variety of materials, from abrasive to hard and soft, with ease. |

Our Crusher Machine Dealers in India assist major industries with dependable solutions for effective and reliable material processing.

The Drehen Equipments & Solutions is an established brand amongst Crusher Machine Manufacturers, Suppliers, Exporters and Dealers in India having the marked to deliver the crushing solutions with customized designed and performed features. Having experience in Automatic Stone Crusher Machines as well as compact models, we provide reliability, efficiency, and hassle-free integration to various industries. We set high standards of quality on our machines and they are supported by strong after sales services. Choose us over other companies because of our innovative design, client customizations and low prices.

These four main crushers include Jaw Crusher Machine, Cone Crusher, Impact Crusher and Gyratory Crusher, with a different unique job to perform in crushing specific type of materials.

The crusher business can be profitable, particularly in India, where it is a major contributor to the GDP. Success is market-demand, efficiency of operations, and strategic management-dependent.

Designs, type and capacity required in your application are the factors that will determine the price of a Crusher Machine. Send us requirements and we will quote per your requirements.