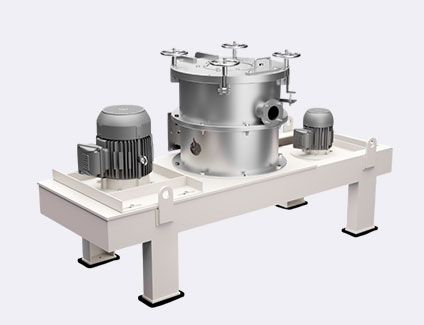

Cyclone Dust Collector

A cyclone dust collector, also known as a cyclone separator, is a mechanical device used to remove dust and particulate matter from industrial air streams. It operates based on the principle of centrifugal force, effectively separating heavier particles from the air stream without the use of filters. Cyclones are widely used in various industries due to their simplicity, durability, and cost-effectiveness.